Surmet is dedicated to providing working solutions that translate into market and performance advantages for our global customers

Surmet Corp. was founded in 1982 with a commitment to provide cost effective advanced material solutions to its industrial customers with a focus on next generation machines, systems and applications. For nearly three decades, Surmet has been a leader in commercializing and scaling up manufacturing of advanced material components, based on critical, innovative R&D carried out in our own state-of-the-art labs. Surmet operates facilities in three states, providing specialized capabilities in ceramics processing, precision polishing, advanced coatings and surface treatments. Our unique and innovative approach has created many successful products, including electrostatic clamps for the semiconductor industry and transparent armor for the aerospace and defense industries. Surmet is a reliable supplier of transparent armor and precision optical ceramic components to major Prime Contractors in the defense and aerospace industries.

Surmet's Corporate Culture

• |

Agile and vibrant corporate structure to support evolving customer requirements. |

• |

Dedicated and competent team to implement continuous improvements. |

• |

Unwavering commitment to clarity, integrity, trust and reliability. |

• |

Strong commitment to deliver superior value to our customers. |

|

|

Mission Statement

• |

To significantly improve service performance of components delivered to our customers, through innovation, R&D and advanced materials Solutions. |

• |

To meet our Customers' highest expectations by providing advanced materials solutions that create significant value over other alternatives. |

|

Surmet is developing weight efficient transparent armor solutions and infrared transmitting optical components based on its ALON® and Spinel optical ceramic materials. ALON® transparent armor provides the same protection as current glass-based armor at half the weight and thickness. Surmet's Spinel is being used in precision optical applications such as missile domes, reconnaissance windows and laser windows.

Surmet's Facilities

Surmet has multiple locations across the US specializing in unique services.

[Learn More]

• |

Surmet Corp. Our corporate headquarters in Burlington, MA spans 17,000ft2 over multiple buildings and serves R&D and ceramics processing needs. 31 B St

Burlington, MA 01803

(781) 272-3969 |

• |

Surmet Precision Optics Our 6,000ft2 West Coast facility focuses on precision optics fabrication. 41618 Eastman Dr.

Murietta, CA 92562

(951) 894-6009

|

• |

Surmet Ceramics Corp. Surmet Ceramics Corp. has a 75,000ft2 one of a kind R&D and specialty manufacturing facility capable of handling tonnage quantities of powder & heat treated blanks of high performance ceramics. 699 Hertel Ave. Suite 290

Buffalo, NY 14207

(716) 875-4091

|

Surmet's Legacy

Before entering the transparent armor market, the highly skilled and innovative engineers at Surmet were busy developing materials and processes for numerous product applications.

[Learn More]

• |

E-Clamps: Surmet developed innovative processes and became the leading Manufacturer and supplier of Advanced Electrostatic Clamps to hold Silicon Wafers. These clamps are still, without competition, the global standard in the semiconductor industry. |

• |

UHP Silicon: Surmet also invented and became the leading supplier of Coated (UHP Silicon) machine components for micro-chip processing chambers where the main goal, among others, is maintaining the highest standards of contamination control. |

• |

Thick Si Coatings: Surmet invented and developed a process to deposit thick (over 100 microns thick) amorphous silicon surfacing for Space Mirror Applications. This silicon is amenable to single point diamond turning. |

Surmet's Analytical Capabilities

|

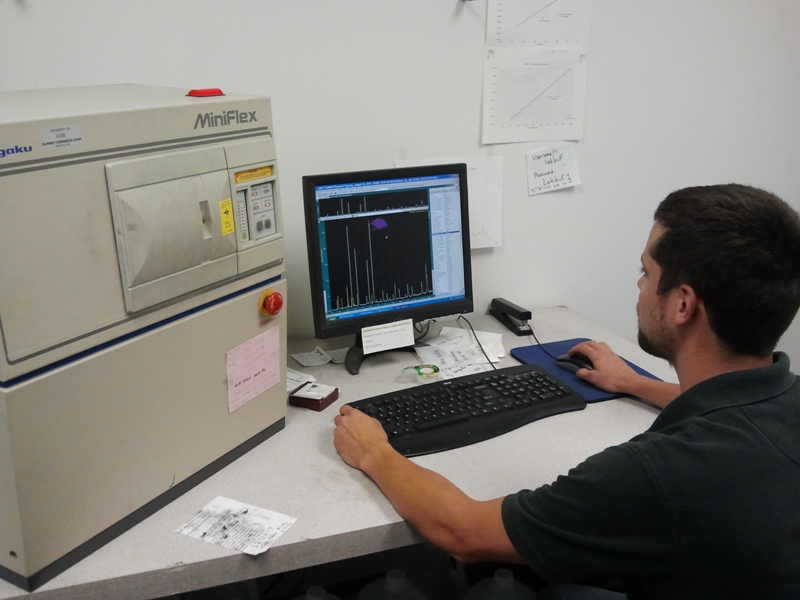

X-Ray Diffraction

X-Ray Diffraction (XRD) is an important tool for characterizing powders and bulk samples. It is typically used to determine composition, phase, crystal structure, and lattice parameters. Our engineers and scientists use XRD for quality control and R&D work.

|

|

Furnaces

Surmet has vacuum, controlled atmosphere and air furnaces capable of synthesizing and heat treating powders in tonnage quantities. Some were custom-designed and for manufacturing and developmental operations.

|

|

Particle Size Distribution

Particle Size Distribution (PSD) is another important tool for quality control of powder production. Surmet's equipment is capable of analyzing powder of sizes ranging from a few nanometers to hundreds of microns.

|

|

Microscopy

Surmet's optical microscopy lab has several stereomicroscopes and compound microscopes for production and research.

|

|

|