Technology and Manufacturing Capabilities

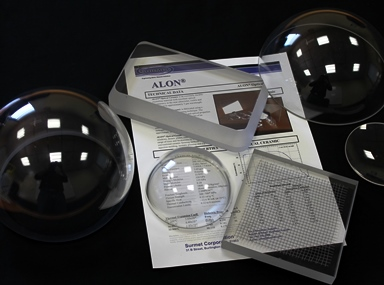

Taking over the development of ALON® from a laboratory demonstration stage in 2002, Surmet is proud to announce the commercial availability of ALON® in large volumes and in really large sizes. Over the last 12 years, Surmet has invested large sums of monies to build up its vertically integrated optical ceramics manufacturing capability. Surmet gratefully acknowledges US DOD funding help in this accomplishment. Creating such a capability required a great deal of patience and attention to detail, and complete commitment, as the return on investment for new technology materials is a slow, uncertain and painstaking endeavor.

Today Surmet manufactures precision ALON® components with consistently high quality, in batches that are in tonnage quantities, and in increasing sizes and shape complexity. Surmet has capability to produce precisely finished ALON components and is the only supplier of monolithic windows as big as 18x35-inch and windows with engineered seams as large as 24x27-inch to the US Defense market. |

|

||||||||||||||||||||||||

ALON® Optical Ceramic's Key FeaturesApplications:

|

ALON® Optical Ceramic Properties

|

Composition: |

Al23-1/3XO27+XN5-X |

Grain Size (typical): |

150-250 microns |

Structure: |

Cubic, Spinel |

Density: |

3.696 - 3.691 g/cc |

Form: |

Polycrystalline |

Melting Point: |

2150°C |

Young's Modulus: |

323 GPa |

Hardness: |

1850 kg/mm2 (Knoop Indent, 200g) |

Fracture Toughness: |

2.0-2.9MPa-m1/2 |

Flexure Strength: |

380-700 MPa |

Thermal Conductivity |

13 W/mK |

Transmission Limits: |

0.22 to 6 microns |

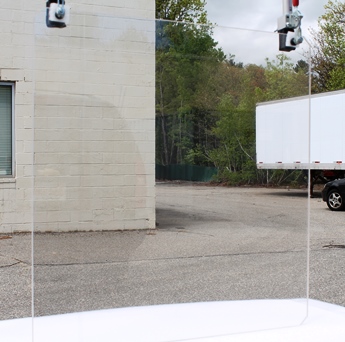

Large ALON® window with invisible engineered seams.