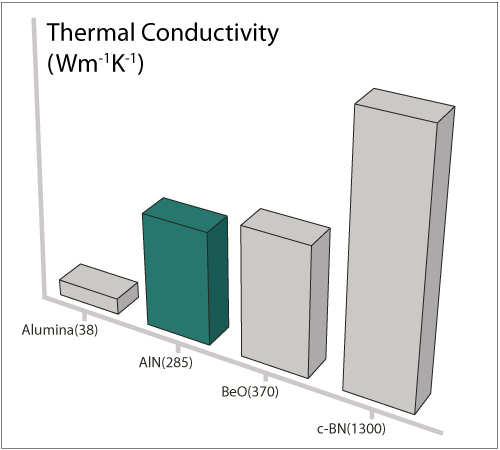

Why AlN is a preferred choice for substrate and thermal management applicationsAluminum Nitride (AlN) is a unique ceramic material that combines high thermal conductivity with high electrical resistivity. Only a few ceramics possess high thermal conductivity: Beryllium Oxide (BeO) and cubic Boron Nitride (c-BN) are virtually the only other examples. However, the use of BeO is restricted due to its toxicity, and c-BN is very difficult to produce. "Thermal conductivity" is the ability of a material to transport heat when subjected to a temperature gradient. In dielectrics like AlN, heat is transferred through lattice vibrations (also known as "phonons"). Materials with simple structure, covalent bonding and low atomic mass generally possess high thermal conductivity. The actual thermal conductivity of a material is affected by factors that hinder phonon propagation. Temperature, impurities, pore size and distribution, grain size, compositional homogeneity and orientation all affect the lattice vibrations, and therefore thermal conductivity. The theoretical thermal conductivity of AlN is about 280 Wm-1K-1. The actual thermal conductivity depends on processing conditions and raw material purity. The presence of oxygen impurities in the lattice is a major detriment; as oxygen displaces nitrogen in the lattice it creaes vacancies that interrupt phonon propagation and scatter the phonons, thus reducing thermal conductivity. Surmet in the only US-based producer of AlN, and has expertise in powder processing procedures required to yield high purity AlN with excellent thermal properties. |

Intrinsic (single crystals) thermal conductivities (Wm-1K-1) of various materials. |

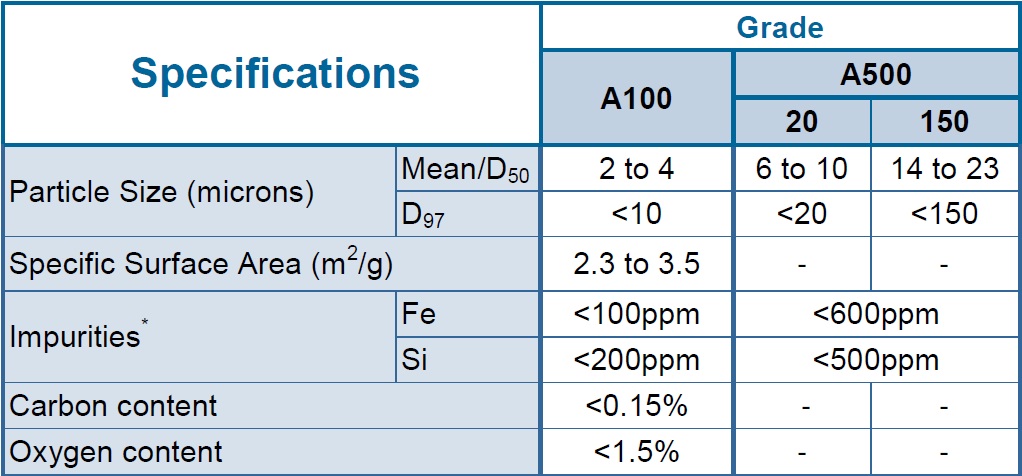

||