|

Surmet's newly developed SuperSapphire™ is the solution for applications that require sapphire's optical transmission.

SuperSapphire™ is made through conventional ceramic powder processing methods. It can readily be made in large sizes and complex geometries at high volume, unlike sapphire, which must be grown as single crystal boules and then fabricated into desired shapes.

Surmet’s SuperSapphire™ is a highly durable polycrystalline ceramic with optical transparency from the near ultraviolet through the mid-wave infrared (MWIR) spectrum. Surmet is developing this material in the form of blanks and finished optics using its own proprietary processes. Target applications include infrared optics such as domes, lenses, sensor windows, reconnaissance windows, etc.

Surmet’s SuperSapphire™ Optical Ceramic

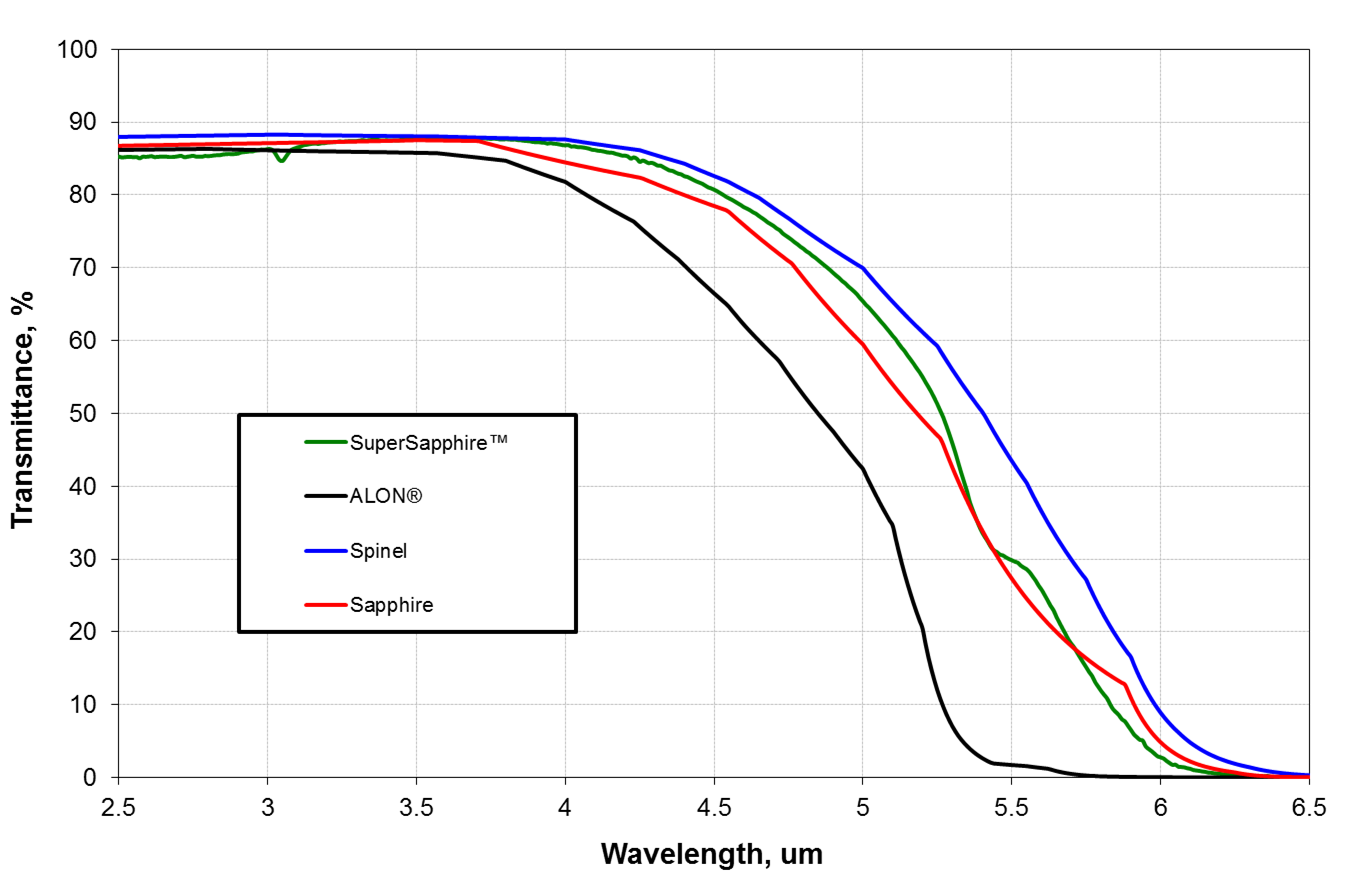

Comparison of Transmission

SuperSapphire™ transmits out further into the MWIR than either ALON® Optical Ceramic or Sapphire.

|

|

|

SuperSapphire™ Optical Ceramic Properties

Composition: |

Proprietary |

Grain Size (typical): |

200 - 300 μm average |

Structure: |

Cubic, Spinel |

Lattice Constant: |

8.060 - 8.080A |

Density: |

3.60-3.61 g/cc |

Form: |

Polycrystalline |

Melting Point: |

>2000°C |

Hardness: |

1600 +/- 50 Kg/mm2 (Knoop Indent, 200g) |

Flexure Strength: |

250-400 MPa |

Transmission Limits: |

0.25 to 6.0 microns |

|

|