Surmet's newly developed SUPERSPINEL™ is a robust solution providing higher MWIR transmission than Sapphire.

SUPERSPINEL™ is made through solid-state sinter and HIP processes, similar to Surmet's ALON®. These processes yield a high strength product without the grain boundary weaknesses known to occur in LiF hot-pressed spinel. Surmet's robust, vertically-integrated process (from SUPERSPINEL™ powders synthesized in-house to precision optical finishing) provides excellent optical quality with no inclusions.

Surmet’s SUPERSPINEL™ is a highly durable polycrystalline ceramic with optical transparency from the near ultraviolet through the mid-wave infrared (MWIR) spectrum. Surmet is developing this material in the form of blanks and finished optics components using its own proprietary processes. Target applications include Infrared optics such as domes, lenses, sensor windows, reconnaissance windows, etc.

Surmet’s SUPERSPINEL™ Optical Ceramic

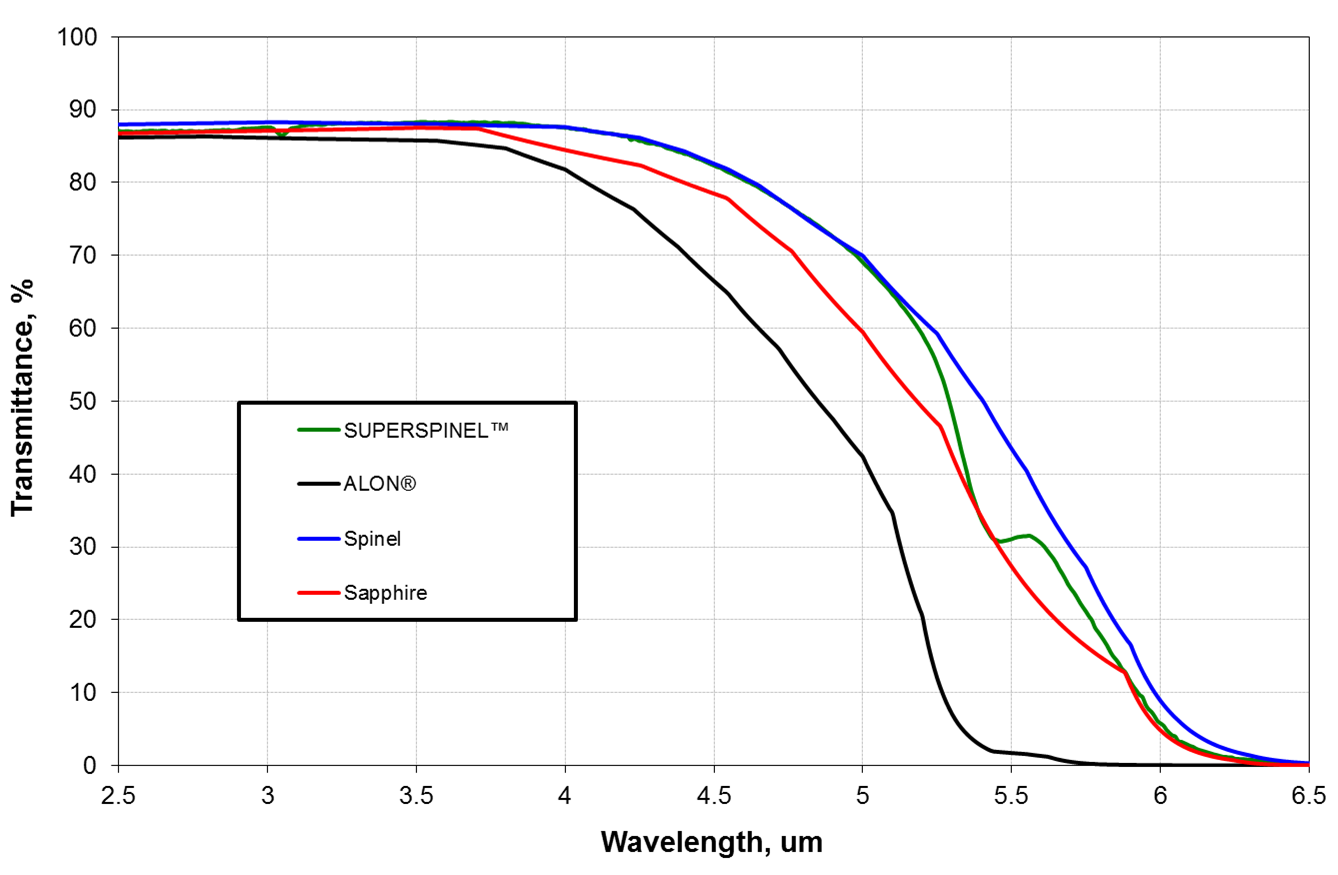

Comparison of Transmission

SUPERSPINEL™ transmits out further into the MWIR than both the ALON® Optical Ceramic and Sapphire.

|

|

|

SUPERSPINEL™ Optical Ceramic Properties

Composition: |

Proprietary |

Grain Size (typical): |

200 - 300 μm average |

Structure: |

Cubic, Spinel |

Lattice Constant: |

8.060 - 8.080A |

Density: |

3.60-3.61 g/cc |

Form: |

Polycrystalline |

Melting Point: |

>2000°C |

Hardness: |

1600 +/- 50 Kg/mm2 (Knoop Indent, 200g) |

Flexure Strength: |

250-350 MPa |

Transmission Limits: |

0.25 to 6.0 microns |

|

|